Your industrial partner for plastic waste processing

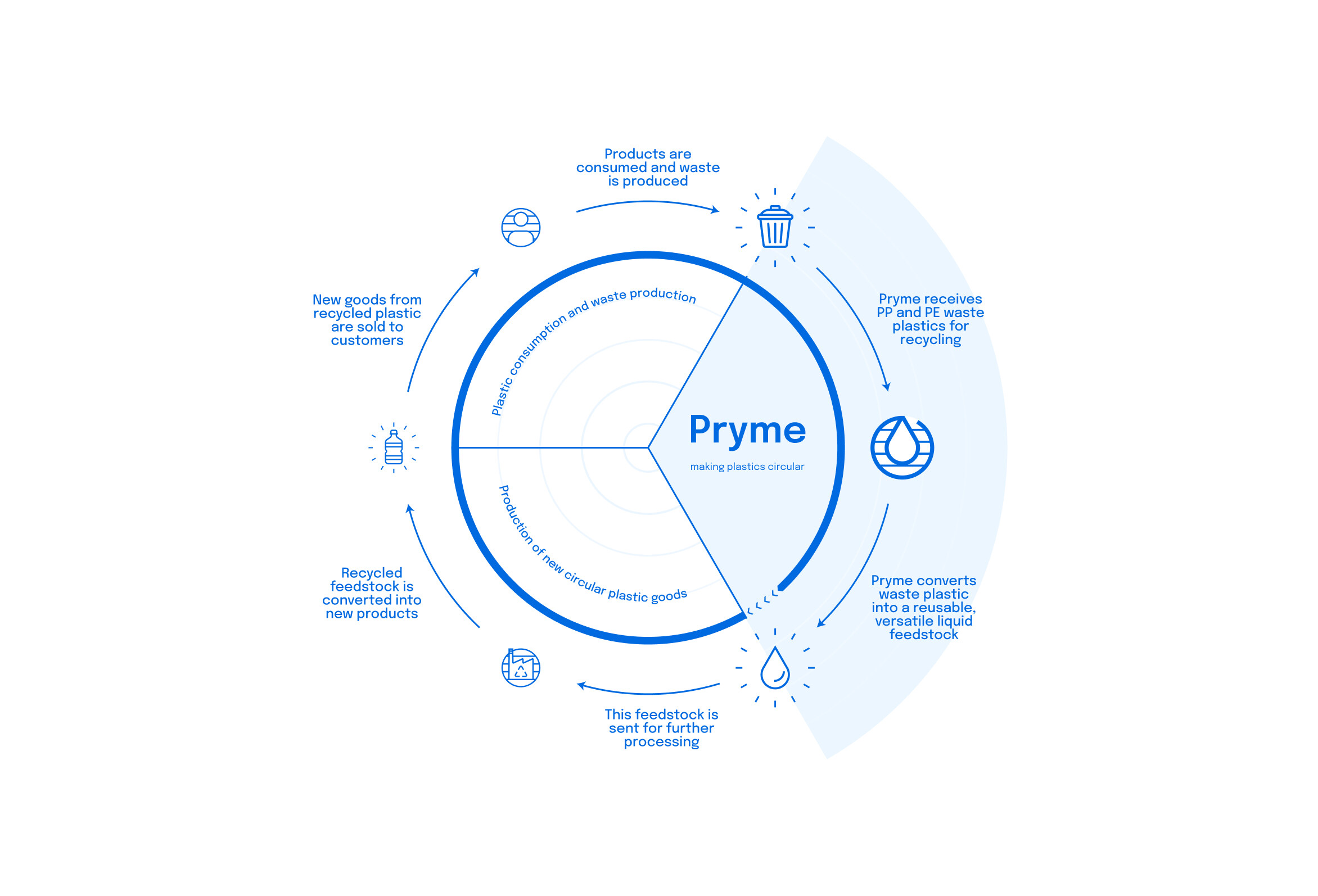

Are you looking to unload plastic waste at volume in a sustainable, circular fashion? Pryme’s industrial chemical recycling technology enables recycling of a wide range of plastics on a scaleable platform.

Chemical processing to close the cycle

At Pryme, we believe that upscaling chemical recycling of plastic waste is an essential step to close the plastic cycle for a wide range of plastic waste materials.

Mechanical plastic recycling is only viable for a selected group of plastic waste feedstocks. That leaves a growing amount of plastic to be incinerated or landfilled.

Prymes’ proprietary plastic pyrolysis technology is an efficient alternative, producing a high yield of high-quality output materials for the petrochemical commodity markets.

Our value for plastic waste processors

Legislation

EU legislation drives the recycling of plastic waste. Combined with an ongoing increase in plastics production, chemical recycling is an essential part of the solution to the circularity of plastics.

EU legislation drives the recycling of plastic waste. Combined with an ongoing increase in plastics production, chemical recycling is an essential part of the solution to the circularity of plastics.

ISCC+ certified feedstocks

With proprietary processes, Pryme is able to recycle waste plastics effectively and efficiently. The pyrolysis oil output conforms with ISCC+ certification requirements.

With proprietary processes, Pryme is able to recycle waste plastics effectively and efficiently. The pyrolysis oil output conforms with ISCC+ certification requirements.

Trusted technology, suitable for scale up

We merged our own R&D with the know-how of a reactor manufacturer with over 80 years of expertise, creating a reliable and scaleable platform with the newest insights in pyrolysis technology.

We merged our own R&D with the know-how of a reactor manufacturer with over 80 years of expertise, creating a reliable and scaleable platform with the newest insights in pyrolysis technology.