Our recycling process: efficient, low carbon and scalable

Pryme has developed a new approach to an existing and proven chemical recycling technology. We optimized the pyrolysis process by adding proprietary characteristics. In this way, we are able to convert waste plastics into petrochemical products with a high conversion rate, on a large scale and with a low carbon footprint – in a highly cost-efficient way.

- 0% We aim to procure 100% of our energy needs from renewable resources

Efficient and scalable technology, unique approach

When embarking upon our waste recycling project in 2008, we chose to combine existing best-in-class technology with novel insights:

Mature technology

Pyrolysis is a mature technology used to efficiently process a wide variety of feedstocks. The concept is relatively simple: when plastics are heated in the absence of oxygen, it is transformed back into an oil-like substance.

Pyrolysis is a mature technology used to efficiently process a wide variety of feedstocks. The concept is relatively simple: when plastics are heated in the absence of oxygen, it is transformed back into an oil-like substance.

80 years of expertise

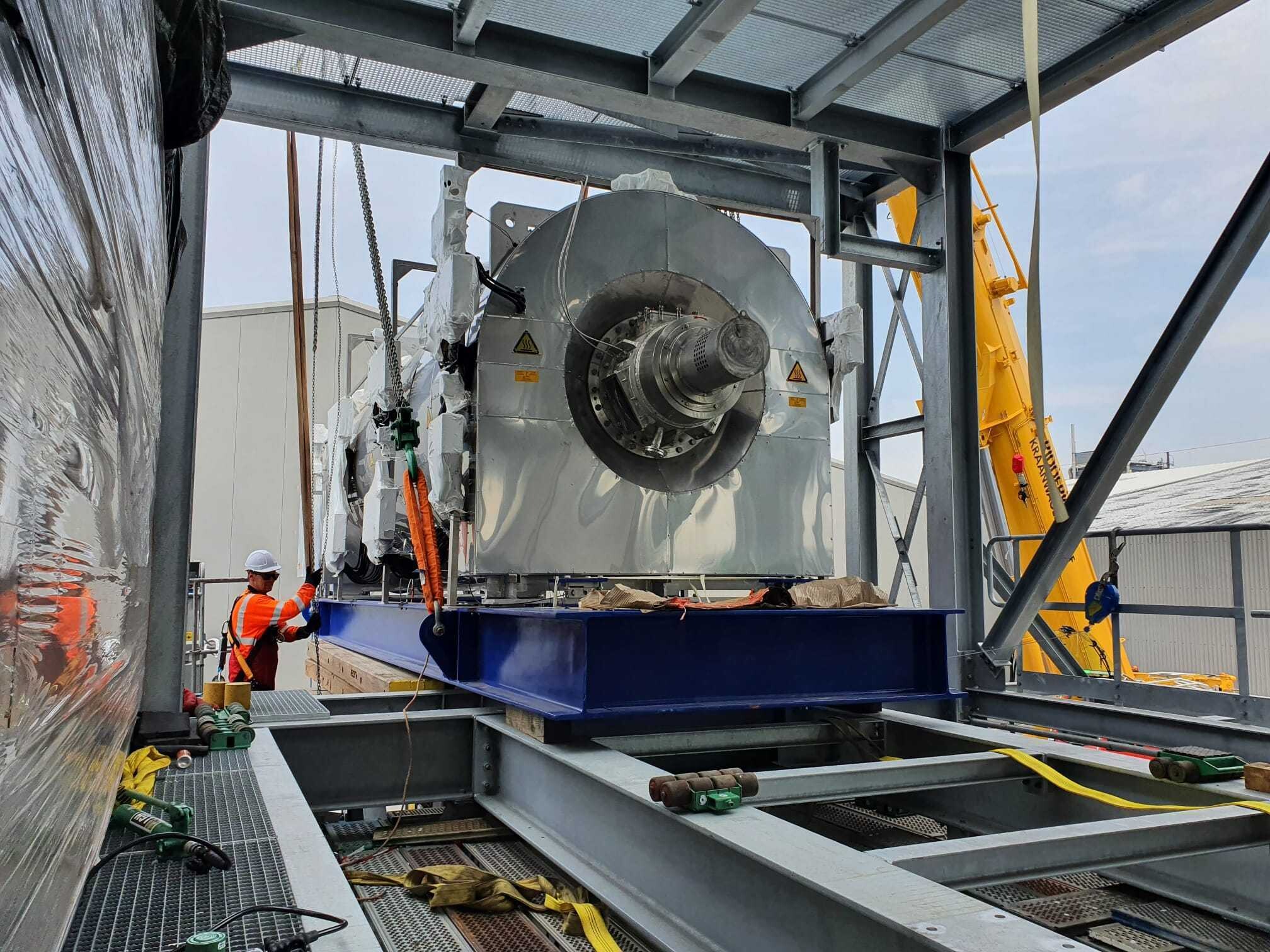

Instead of developing our own pyrolysis reactor, we teamed up with a reactor manufacturer that boasts over 80 years of expertise in this area.

Instead of developing our own pyrolysis reactor, we teamed up with a reactor manufacturer that boasts over 80 years of expertise in this area.

Our own process control

Together, we took the existing technology to a new level and developed our own process control:

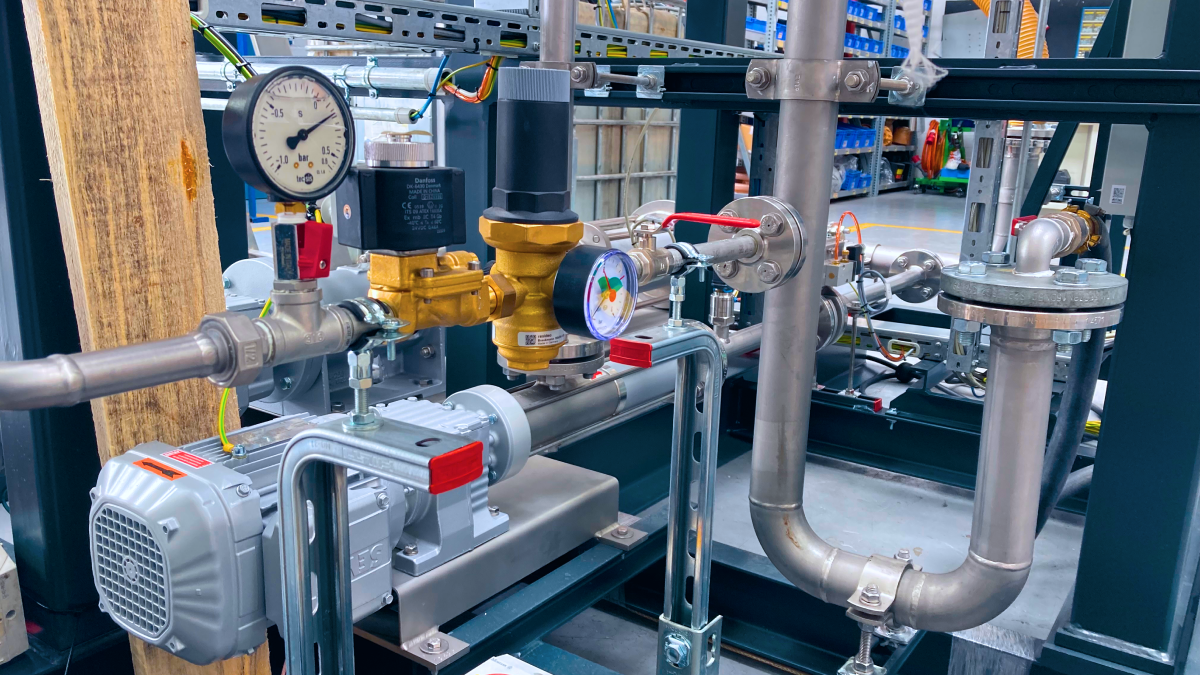

Temperature control: We use extrusion technology to heat the plastic to a specific and controlled temperature, creating an air-tight paste.

Reactor heating: The reactor ensures a very precise, controlled application of heat.

Removal of key contaminants: We are enhancing our process in order to remove key contaminants.

High conversion rate: our process enables a high conversion rate of waste plastics.

Together, we took the existing technology to a new level and developed our own process control:

Temperature control: We use extrusion technology to heat the plastic to a specific and controlled temperature, creating an air-tight paste.

Reactor heating: The reactor ensures a very precise, controlled application of heat.

Removal of key contaminants: We are enhancing our process in order to remove key contaminants.

High conversion rate: our process enables a high conversion rate of waste plastics.

Higher capacity

We use a reactor with a substantially higher capacity – to ensure economic feasibility.

We use a reactor with a substantially higher capacity – to ensure economic feasibility.

Chemical recycling explained

What is chemical recycling exactly? How does it work? And why do we think it holds such enormous potential in the circular economy?

In our latest article, you'll find the answer to all these questions.

Cost leadership

Our technology and process are rooted in broad experience of industrial processes and the result of years of R1D and technology improvements.

Our cost structure is efficient, building on scalable existing technology and production at industrial scale.

Low carbon footprint

Ensuring circularity and low-carbon processing go hand in hand at Pryme.

The chemical recycling of plastics produces substantially less CO2 compared to incineration. Moreover, we aim to procure 100% of our electricity needs from renewable sources, thereby ensuring the significantly low carbon footprint of our processes.